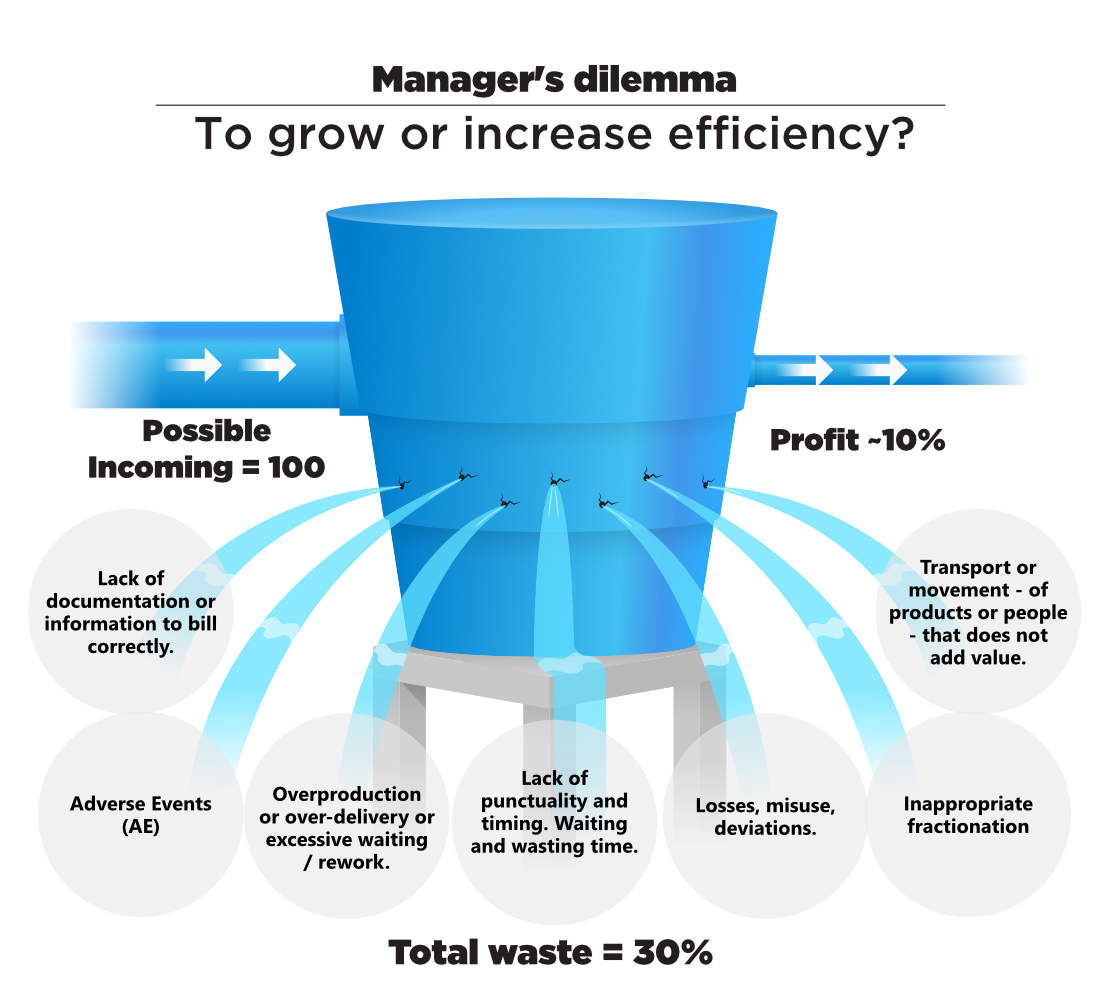

The reduction of waste is important because it has a symmetrical impact on pre-tax profits. In other words: less waste = more profit.

As human beings, we are more inclined to explore new territory than to manage more efficiently what we already have. Managing is a tedious and often unrecognized task, but it is a job we must tackle with energy.

We define waste as all those tasks or expenses that do not add value to the end customer and their needs.

The main concepts are explained in the picture above.

Seen from an economic point of view, doubling the profit would require doubling the capacity of the hospital and its business. Imagine the investment of a large hospital to double profits. But if we manage to reduce 1/3 of the waste, we will have achieved another 10% profit, that is, double. That is the true meaning of reducing waste.

But how can we reduce waste?

A quality management system would help to work on this with consistency. It has to have several people and be well structured, because you have to MEASURE all processes and their results. In industry we are used to measuring almost everything. This is not the case in the healthcare sector. Curing, eliminating pain and suffering is more important.

But managers must work like jugglers who keep several balls in the air. Caring for the health of patients, organizing the logistics of the entire hospital, attending to the needs of professionals from all teams, whether clinical or administrative, and maintaining the financial health of the institution. All of these are important, but without economic efficiency it is difficult to meet the other demands.

Within the technologies, Lean stands out for seeking closer processes and analyzing the true value of each task. Many of Toyota’s methodologies, applied for years in industry, are now valued to improve hospital processes.

Having complete information to be able to compare and measure, billing and receiving revenue for this service is probably the first step, to know the size of the monster we have to master.

Even if a quality structure for patient and waste safety is established, the question never ends there. Like almost all objectives, you have to engage, raise awareness and create a group culture with knowledge and tools to achieve the objectives.

If transporting products is a cost, keeping 15% or 20% of the returns of medications dispensed by the Central Pharmacy is wasteful to say the least. Complaints from practitioners about not having all the prepared and necessary items at their disposal, and also having to travel frequently to the place of supply, is a common complaint in many countries.

The products that are used and allocated to overheads do not help to manage efficiently, because we do not know which process is profitable and which is loss-making.

Product losses due to inventory variances, which in many cases are as high as 18%, need to be controlled and reduced. Automatic electronic control helps to control effectively, but the information that must be entered into the system, whether on paper or electronically, slows down the daily activity and contains more errors and incomplete information.

Inadequate fractioning of products and medications are cost drivers that do not add value to the end customer and are wasteful. Expensive cleaning products can be fractionated within the hospital before being dispensed, as can medications.

When we have two people performing the same task, it is very likely to be wasteful, perhaps due to lack of proper training.

Summary

Even without reaching any resolution, if you measure waste, you will have already made a breakthrough, because you will provoke a change of attitude in top management to allocate resources to this end. The most profitable organizations are those that invest the most in quality.

Victor Basso

Director of Opuspac University (corporate university)