Opus MK5

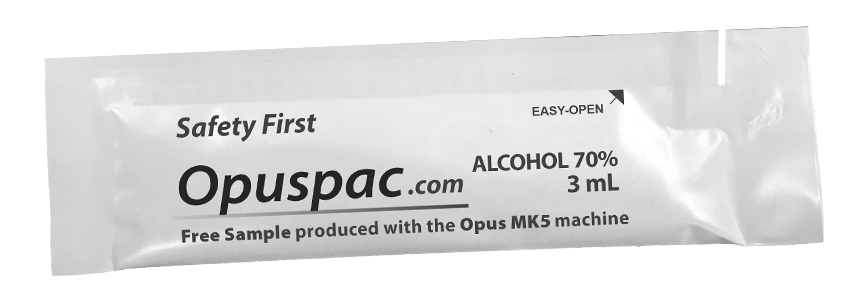

Unit dose packaging for oral liquids.

For alcohol gel syrups, creams, herbal medicines or cleaning products.

“The oral liquid fractionation machine MK5 allowed us to be more suitable in the dispensing process of most meds in the liquid pharmaceutical form of oral/enteral use previously available in multi-dose vials.

With the acquisition of this automated solution, the pharmacy service had a significant increase in productivity in the Pharmacy Unit Dose, began to produce sachets with fractional volumes of liquid meds fully traceable, with DataMatrix code, with safety alerts in their packaging, with signs for controlled medicines and for those with reduced validity.

It decreased losses due to bottle sharing and minimized risks of adverse events due to the availability of these drugs in care units. Sachet packaging is economical, practical, easy to use and open.”

An amazing solution of compact size and highly functional

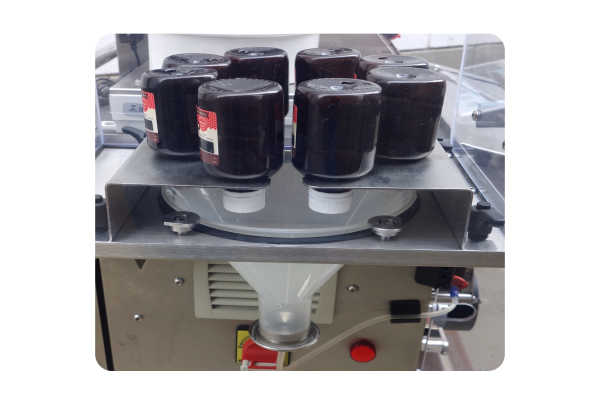

Opus MK5 is a mobile, compact and highly functional oral liquid fractionating machine. Starting from a coil, it fractionates a quantity of liquid, prints a package and seals it, completing the unit dose process.

It can be used for any liquid in the hospital, from syrups and creams to hygiene and cleaning products.

Opus MK5 packaging prevents waste and replaces higher cost packaging and bottles. The machine has sterilizable ducts and the sachets are printed with the information of the oral liquid.

Sterilizable machine duct. 2 units included.

Device to fully empty the liquid from the bottles. The funnel has control of the end of the product.

Occupies a small area in the Hospital Pharmacy

An area of 1,30 x 1,30 is sufficient for operation.

Specifications

width: 30 or 500 mm:

Length: 75 or 250 mm.

Uses peristaltic pump.

Dosage accuracy from 3 % to 5 % for small volumes.

Productivity: up to 20 units per minute.

Input power: 990watts.

Very functional packaging, opens very easily and avoids the use of cups.

It has a sensor wich stops the machine when the liquid is over.

Easy operation.

Guaranteed return on ivestiment.

Opus MK5 brochure, machine for fractionation and unit dose of liquids - syrups, creams, herbal medicines, alcohol gel, cleaning products and others (PDF).

Size: 6.09 MB

Register to download