Global-class Robotic Unitarization

• Robotic unit dose re-packing, preserving primare package.

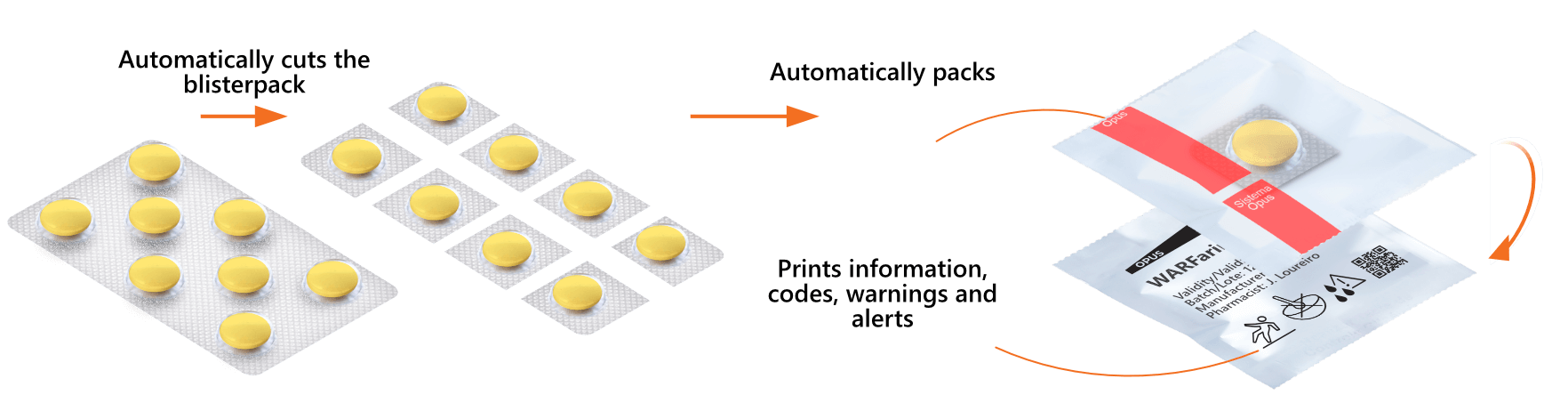

• Solid oral meds, cuts blisterpack prints and packs unit dose.

• Also prints and packs unit dose of ampoules and vials.

From Blister Cut to Print

Select cutting parameters in the operator interface screen before cutting and printing and , avoiding all possibilities of wrong identification.

Synchronize with HIS through our exclusive Opus 5.0 Software. Includes 100+ minibula instructions and alerts with drawings for 2000+ medicines.

All mechanism is enclosed giving very low noise in the room.

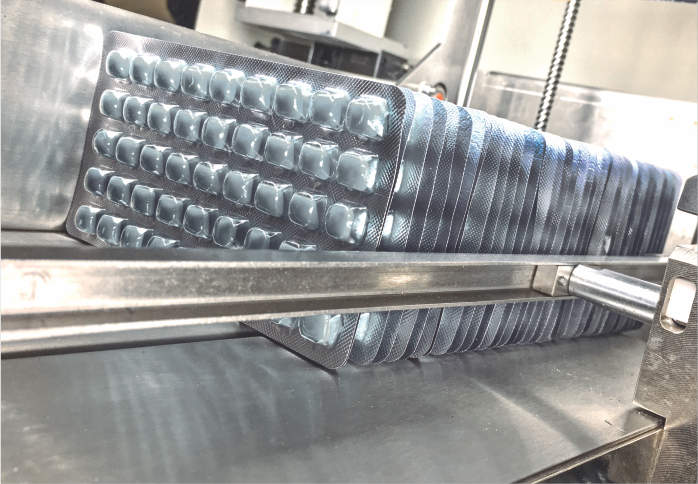

Produce easy tear off strips of «n» units for tidy stock organization.

Prints additional color on the package for medicine class identification.

Production rate until 1200 cuts per hour (30 doses per blisterpack).

Classic configurations of the blister to cut

Cutting System

• Minimum distance required between bubbles is 2.5 mm.

• Distance from the edge to bubble should be 3.5 mm.

• Orientation to 45 degrees is possible.

• Alternate position of pills is not a problem.

• Also cuts blister with aluminium foil in both sides.

• Internal useful capacity is up 120 mm, can be fed with 40 cards.

• This system usually cuts in between 70 and 90% of the required cuts in the hospital.

AIVAK PRO Advantages

Add a variety of tools to your process

To keep the pill inside the blister without microbiological and contamination risk is a huge pharmaceutical advantage.

To check printing information, color and shape of blister on both sides before each cutting cycle is also a safety tool.

To insert information of the route of administration, alerts and advices to each med with an additional color alert is a required safety procedure. Serial code number can be added for further tracing.

Opuspac System Tools (see details in our E-books), includes many other safety methodologies.

Higher Production Rate and Reliability

With AIVAK PRO you can convert meds in unit-dose before sending it to stock, because high output makes possible that goods received today are processed today or tomorrow.

Carton box packages are discarded in the begining of the process so the product has no commercial value after that, avoiding loses.

Roll stock has 15,000 units making the loss of time to change roll 7 times less than in other equipments.

Do you want Safety, High Productivity and Cost Reduction for a Hospital of up to 1,100 Beds?

• Now it is possible to keep tighter safety procedures due AIVAK PRO robotic technology

• AIVAK PRO high production allows to serve hospitals with up to 1,100 beds (one shift)

• Opuspac has a total Logistics cycle with robotic machines included

• With increasing healthcare cost everywhere is most important to choose technologies reducing fixed cost

• Opuspac attends more than 950 hospitals in 27 countries. CE Certificated

More Information

Discover how Opuspac solutions can provide savings and safety to patients through complete automation.

AIVAK PRO Brochure (pdf, 3.92 MB) Opus Flag Brochure (pdf, 3.99 MB) Brochure Opuspac Equipment + Software (pdf, 6.27 MB)