Inkjet Labeling for medical materials.

Prints texts and bar codes for identifying mats and meds

- Prints on a variety of materials, including porous plastics

- Quick setup. Does not require height adjustment

- Prints on curved surfaces

Safe Stock – Prevents waste in the Hospital Pharmacy

Include text and a barcode on hospital supplies and medications.

Vídeo

Features

· Does not require adjustment of the distance between the printer head and the product.

· Tilted position conveyor for operator convenience.

· Uses non-toxic alcohol based ink with instantaneous dry.

· Easy format change in 5 seconds.

· It has inlet and outlet reservoirs of 26 liters each.

· Labeling speed: up to 3,000 items per hour.

· Communicates with the hospital’s ERP (optional software).

· Stainless steel printer.

· Power required: 220 volts, 3,800 watts.

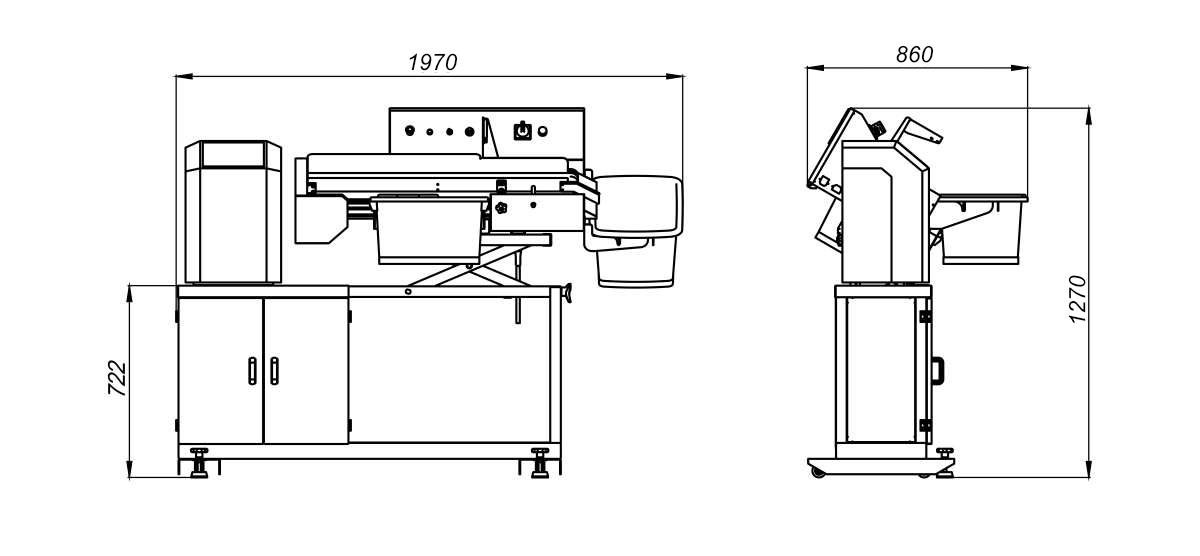

· Equipment weight: 150 Kg.

· Number of operators: One.

· Substrates: paper, cardboard, porous plastics, etc.

Know more

· 7″ color touch screen HCI

· Prints text, linear and 2D bar codes.

· Alert system.

· Reduced ink cost, with 800 ml cartridges that last for months.

· Access to maintenance and production history.

· Does not require compressed air.

· Operator access by password.

· Communication: Ethernet, USB or SD.

· 1 year warranty.

Know more

Opus Ink machine, for direct printing of characters and codes for identification of mats and meds (PDF brochure).

Size: 5.03 MB

Register to download