The unitarization of solid medicines, i.e. tablets and capsules, is one of the most critical and essential steps within the supply chain process in an institution and one of the most important for the organization and reduction of medication errors. The purpose of this stage of the process is to preserve the information on the primary packaging of the drug, which is essential for it to be administered safely. Some of the information present on the packaging are: name, validity, dose, barcode/Datamatrix, batch, manufacturer, as well as alerts related to medications, such as risk of falls, not being administered to pregnant women, High Alert medication and others, and can be customized according to the characteristics of the institution.

As a complement, the same recommendations apply to the identification of ampoules.

Improvements in this process are essential for quality assurance and patient safety and provide some advantages such as: immediate entry of the medicine into the patients’ account and automatic cancellation of stocks, traceability and differentiation of medicines that can cause harm to patients at the time of administration, such as controlled, high surveillance, chemotherapy, cytostatics, drugs with similar names and sounds (LASA), among other classes; In addition to providing nursing, at the time of administration, with a clear and effective reading of all the necessary information of the med in the unitarized packaging, to ensure safety in the bedside process, providing easy usability by the care team and reducing stock levels in hospitals, compared to those who do not perform unitarization, a number that currently approaches 60%.

To ensure a safe and efficient process we must meet the minimum requirements:

- Perform hand and equipment hygiene to be used before starting the process.

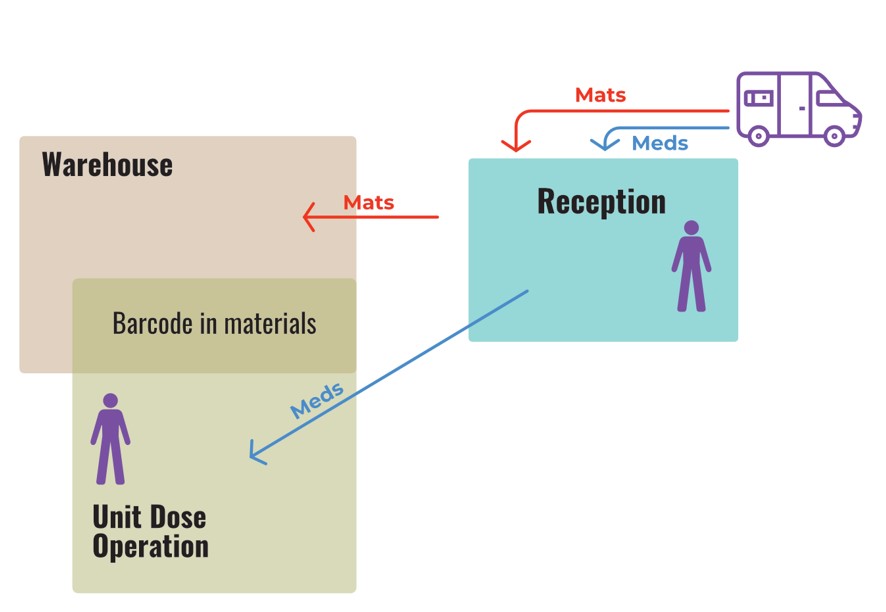

- Have an exclusive room dedicated to this activity, with adequate facilities to comply with laws, with proper space, easy cleaning, with sufficient lighting, sink for hand hygiene, controlled temperature and humidity, ergonomic furniture and, when possible, that is close to the receiving area, to avoid unnecessary movements.

- At the time of unitarization of the drug, unitarize only one product at a time, to avoid risks of mixing the medications, causing serious harm to patients. Start by checking the batch and the information that will be printed on the unit dose packaging, comparing it with the information on the main carton of the medication. If possible at this time read the barcode of the med to enter the information into the machine and conduct the conference. After the end of the process on the unit dose machine, carry out an inspection on the equipment to check that there is no medicine left; perform visual inspection and counting of unitarized meds; Seal this medicine in plastic boxes with the name and quantity of the unitarized medicine, duly identified, for subsequent shipment to the Central Pharmacy.

- Separate the meds by their batches, that is, if at this time the medicine has more than one batch, work with one batch at a time, comparing it with its respective primary packaging. It is also recommended to organize high-cost or specific drugs in a serialized manner.

- The pharmacist, together with the Quality and Patient Safety team, must create control indicators for the process, in order to ensure that after the unitarization of each medication it has the necessary safety and that there are no failures in the process. You can create a spreadsheet with all the data of the unitarized drug and, after the end of each product, perform the physical conference, to avoid errors in the process.

- Conduct training for all those involved in the unitarization process and avoid the rotation of people in the use of equipment, to avoid possible damage and lack of unitarized medicines for patients. Ideally, have a reference employee on call to operate the equipment.

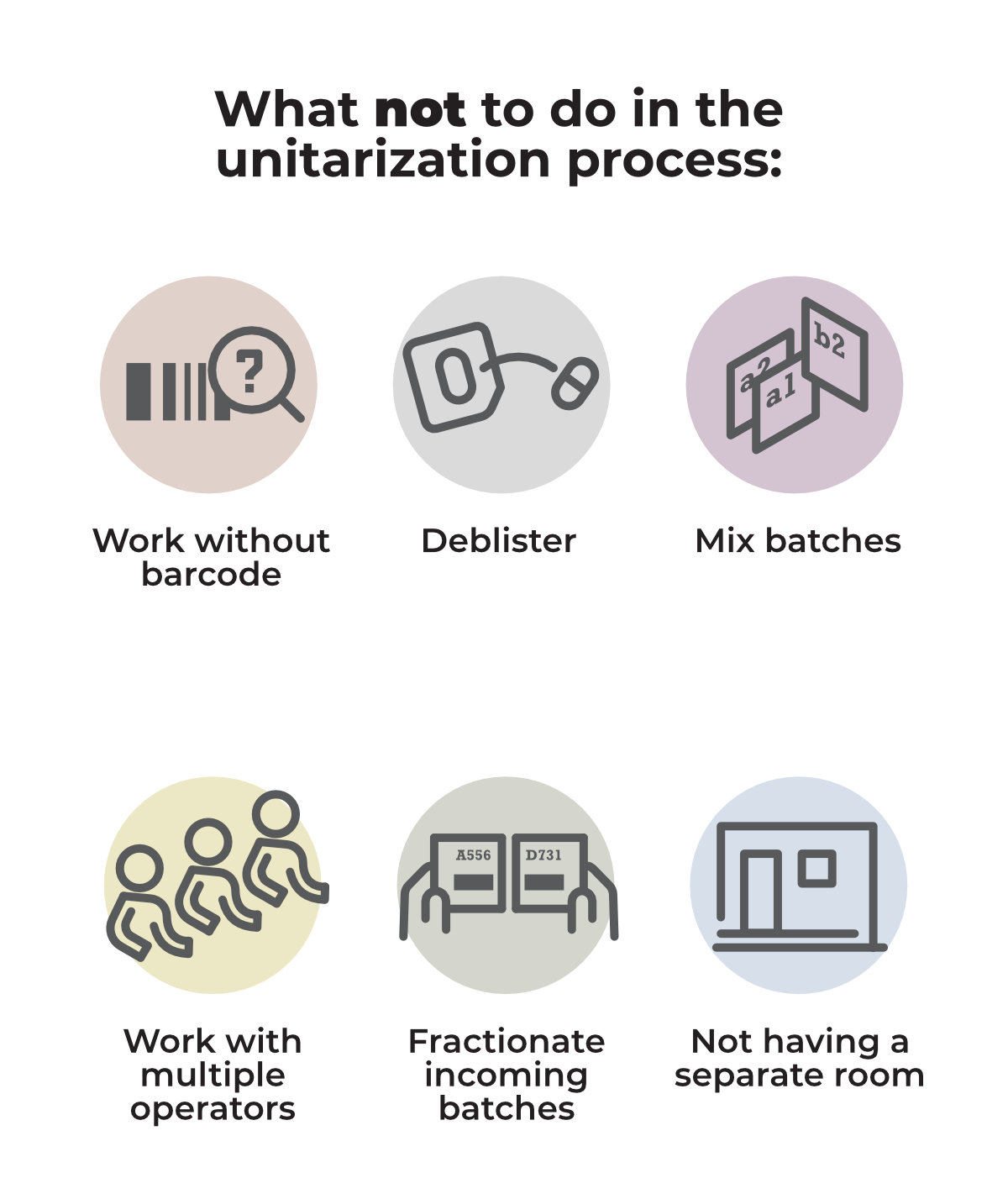

It’s important to remember what should not be done in this process, that is, it is strictly discouraged:

- Working without barcode (CB): It is essential that the entire process of unitarization of medicines is carried out using the Barcode (CB) system. This will ensure traceability and safety, minimizing errors and ensuring that each medication is properly identified and unitarized before any procedure.

- Deblistering medicines: Medicines in tablets, capsules and dragees, must always be unitarized in their respective ampoules, to preserve their physicochemical properties, guaranteed by the pharmaceutical industry, in addition to continuously following the safety standards established in the process and avoiding any risk to the health of patients.

- Mixing batches in the unitarization room: As recommended above, batches should be properly separated and one batch should always be worked with at a time so that there is no confusion or mixing of different medications. This practice promotes traceability and avoids possible errors in the dispensing of medicines to patients.

- Working with multiple operators in the room: Ideally, you should work with only one operator at a time and not work with multiple employees in the same room. Each operator should be duly authorised and able to carry out its functions in accordance with established procedures. The unitarization of medicines should be carried out only by designated and properly trained operators, avoiding any errors in the process.

- Fractionating input batches: The fractionation of batches of medicines should not be carried out in the unitarization process, it must be strictly following the established protocols and guidelines. It is important to ensure that each batch is correctly identified and that there is no risk of errors or incorrect mixing during the process.

- Not having a separate room for unitarization: It is imperative that the unitarization of medicines be carried out in a specific room and duly designated for this purpose. This measure aims to avoid any possibility of errors in the process and ensures a controlled and suitable environment for safe unitarization.

The dispensing of medicines is another essential activity within the Hospital Pharmacy, that is why we mention it here, because it is the stage that follows the unitarization process. Therefore, it is necessary to pay special attention to the choice of the distribution system, appropriate to the characteristics of the institution, with the use of technologies, automated smart lockers, barcode reading and separation of high-surveillance and psychotropic drugs, duly identified and separated from other items and personally delivered to nursing stations.

The work of the pharmaceutical professional in these mentioned processes should be guided by the following objectives: to have an organized and safe unitarization system; a simplified distribution system to ensure compliance with medical prescriptions; correctly administer medications to patients, mitigating errors; reduce the time of the nursing team with activities that should be of the technical-administrative team; and enhance its role in the multidisciplinary team, providing the institution with an active and economically efficient management, with the reduction of costs and waste, and a safe, effective and rational pharmacotherapy for patients.