The case described is a pilot project of a hospital complex consisting of 6 hospitals with a total of 1,800 beds.

In July 2020 the Santa Casa de Misericordia of Porto Alegre acquired the Opus MK5 automated machine for the automatic fractionation of oral liquid meds.

Opus MK5 is marketed by Opuspac Hospital Automation and manufactured by Ibtek Innovative Solutions. Its use in the hospital med process has generated great savings, allowing less waste, lower costs with materials/meds, more safety, quality, and agility in the flows.

Generally, the fractionation of oral liquid meds, in the hospital pharmacy is carried out:

- Manually through disposable syringes (individualized dispensing of meds).

- By dispensing bottles of liquid meds to the different sectors of the hospital (collective dispensing of meds).

In both situations, meds are stored in the care units and used on patients by the nursing team in accordance with medical prescriptions.

In both cases, wastage of drugs and materials is common, since the consumption of disposable syringes is high and the control of the use of drugs dispensed by vials for hospital sectors is complex.

In addition, there are many possibilities of different adverse events for patients:

- Risk of cross-contamination of medicines due to excessive handling

- Risk of using expired meds

- Risk of incorrect administration of med to patients when changing patients or med or changing volume and dosage.

Regarding the financial issue, the two situations of manual fractionation of oral liquid meds also require high monthly investment amounts.

For example:

– For 200-bed hospitals.

In collective distribution, where bottles of oral liquid medicines are stored in the health care clinics, the purchase of bottles of medicines is high to serve all sectors.

In many cases, the payer could not be billed for this medicine, resulting in a loss of R$ 1 million in invoicing. In other cases, the waste in each bottle is over 30% with a waste of R$ 345.000,00 or more.

In individualized distribution, where the fractionation of oral liquid meds is done through disposable syringes, the purchase of syringes to store the meds is high.

The annual expense exceeds R$ 200,000.00, which is more than the cost of the equipment.

Value of 12.000 sachets with liquid = R$ 1,400.00 / month

SANTA CASA OF PORTO ALEGRE BEFORE OPUS MK5

During the planning of the project, a retrospective study was conducted to evaluate the financial losses of Santa Casa de Misericórdia de Porto Alegre, with the manual fractionation of oral liquid meds.

The period analyzed was 5 months, from May 2019 to October 2019.

In this evaluation, it was presented that the biggest problem was related to returns.

The lack of amortization in the system and the use of meds by patients showed that only less than 10% of the production of fractionated oral liquid meds dispensed by the pharmacy was accounted for in patients accounts after use.

In the hospital, this process of including medicine used by patients in their accounts was manual.

And due to the day-to-day rush and difficulties in getting the system up and running, Santa Casa was missing a significant amount from payers (health insurance or public health – SUS).

According to what was presented by the coordinator of the pharmacy service of Santa Casa de Misericórdia de Porto Alegre, at the 6th SINDIHOSPA Hospital Pharmacy Conference in October 2021, the difficulty in billing the use of medicines by patients, allowed that in the 5 months analyzed, the costs lost by the pharmacy, due to the lack of control of medicines, reached R$ 480,000.00.

These values, presented by the pharmacy, alerted the management to the high costs of manual fractionation of oral liquid meds. However, with the automation of fractionation, in addition to reducing costs, more quality and safety in the process would be guaranteed.

In view of this, this retrospective study and the presentation of the solution to this problem led to the rapid approval of the project to acquire the OPUS MK5 machine to automate the fractionation of oral liquid meds at the Santa Casa de Misericórdia Hospital Complex in Porto Alegre.

PREPARATIONS TO RECEIVE OPUS MK5

The machine was deployed in July 2020 and initially the control of high-cost and high-risk drugs was preferred.

To define which meds would be automatically fractionated by the OPUS MK5, analyses of oral liquid prescriptions in hospitals were performed.

The following table describes the selected medicines, their doses and the volumes fractionated by the machine:

All med fractionation requires attention, cleanliness, organization and time, as it is extremely meticulous and important. With fractionation automation, the processes are cleaner and more controlled.

But any distraction and/or interruption during fractionation can also cause an error with a high potential for harm to patients.

The care in the preparation and handling of fractionated drugs is described in the regulation RDC 67/2007, which guarantees the quality of production.

The area provided in the pharmacy for the OPUS MK5 was 1.30 m2 x 1.30 m2, sufficient area for its operation.

The software available with the OPUS MK5 machine allows for better planning of the production needs and use of medicines, ensuring greater efficiency and allowing better stock control.

In addition, the better presentation of medicines also avoids wastage and process failures with respect to expired medicines. Even in the case of drug fractionation, the shelf life is reduced by 75%.

The packages are presented in special 3-seal sachets, which can also be color-coded according to each medicine.

What does the machine print?

In addition to the ideal and always legible information that every package should contain: drug name, dosage, expiration date, batch number, bar code and name of the responsible pharmacist.

The new packaging offers specific information about the meds: risk of falling, route of administration, risk of bleeding, med on time, high-alert meds, possibility of different colors stripes on the packaging, among others.

Along with these positive features, they also take up less space, are easy to open and cheaper.

They cost an average of 10% of the value of the syringes.

Dispensing oral liquid medicines in flexible containers also allows the system to be used to read med barcodes. Solving the serious problem of the lack of entry of meds used by patients in the accounts.

The barcoding of the containers facilitated the checking and settling of meds at the bedside, at the time they will be administered to patients, which may have a serial code.

These changes ensured greater safety in the med process and avoided waste, responsible for high costs at Santa Casa de Misericórdia de Porto Alegre.

MACHINE IN USE

According to what was presented by the pharmacy coordinator of Santa Casa de Misericórdia de Porto Alegre, at the 6th SINDIHOSPA Hospital Day in October 2021, the data presented were:

The average monthly production of fractionated medicines, during 12 months, at Santa Casa de Misericórdia, before the OPUS MK5 was 8,300/month.

After 12 months of using the OPUS MK5 machine, Santa Casa de Misericordia’s average monthly production increased by approximately 250% to 28,400 sachets/month.

In addition to significantly increasing the productivity of unit dose medicines at Santa Casa de Misericórdia de Porto Alegre, the installation of the OPUS MK5 machine reduced pharmacy costs with mats/meds and waste.

In addition, this allowed to give more attention to:

- Hospital logistics

- Efficient communication between sectors

- Readjustment of pharmacy employees’ work schedules (automated machine one employee per operation)

- Stock control (purchase, distribution and use of medicines)

- Equipment preventive and corrective maintenance

- Controlled medicine alerts (meds of high vigilance).

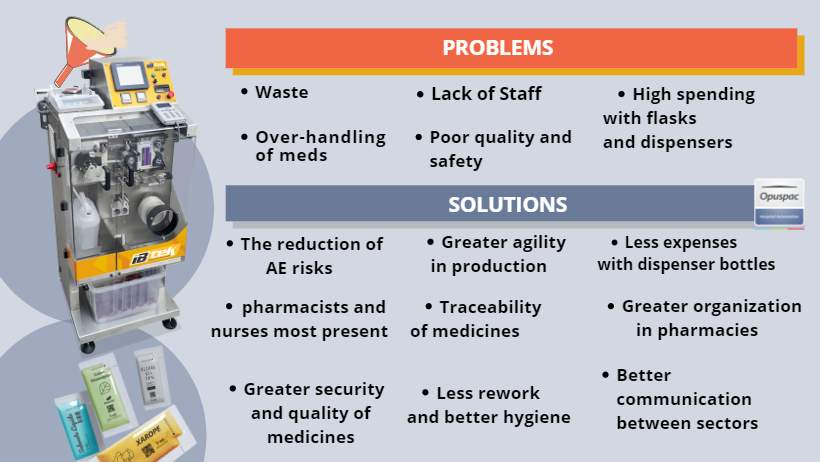

The main difficulties of hospital pharmacies have been solved with the right investment.

Solutions with the OPUS MK5 machine

See Opus MK5 in action:

CONCLUSION

At the 6th SINDIHOSPA Hospital Pharmacy Conference, in October/2021, the Pharmacy Coordinator of Santa Casa de Misericórdia de Porto Alegre presented that the acquisition of the OPUS MK5 machine has become for the hospital complex, a source of economy, in addition to more safety and more quality for the institution.

The return on investment (RoI) on the acquisition of the OPUS MK5 machine was 7 months.

And the great results obtained have enabled significant improvements in the hospital’s med processes:

- Improved traceability of meds.

- Increased safety in the administration of oral liquids.

- Greater agility in the production of unit packages

- More hygienic fractionation.

- Better communication between teams.

- Reduced costs with dispensers, medicine bottles and waste.

- Decrease in pharmacy expenses due to the consumption of oral liquid meds not received by payers.

- A more organized pharmacy

- Service to branches of the hospital complex

- Reduced risk of errors and harm to patients (AE).

Therefore, it is possible to affirm that the automation technology used in the machines distributed by Opuspac, can reduce and or put an end to the usual bottlenecks in hospital pharmacies. Such as lack of organization, lack of employees, waste of materials and medicines, rework, returns and delays.

All these situations are part of the daily life of hospital pharmacies and deserve proper attention, so that recurring problems in the dispensing of medicines can be solved.

With the OPUS MK5 machine, it was possible for pharmacists to be less busy with pharmacy operational difficulties and more available for clinical pharmacy (patient care) and for nurses to be less busy with the preparation of liquid med doses and more available for attention in patient care, providing more safety and quality in the administration of meds to patients.

The integration of the pharmacy teams with the nursing team allowed for more humanized and safer patient care.

This successful project guaranteed pharmacoeconomics actions at Santa Casa de Misericórdia de Porto Alegre, with excellent financial and care results. It is possible to see how automated machines should be more widely used in hospital pharmacies.

After all, the high values saved by the Hospital Complex, presented in the previous case, guarantee that ideal planning with the right actions and adequate follow-up allows the right investments to be made for the right difficulties.

It is necessary to intensify safety strategies to prevent errors and ensure Patient Safety.

Victor Basso

Director of Opuspac University (corporate university)